Its been a while since a post, I have been slammed traveling and working on getting the MLS shop ready. Its been such an adventure the last months of moving, setting up and traveling for projects, so glad to be around such amazing people all the time pushing for the future and how we make it happen.

I want to start off with some MLS shop stuff to give you an idea of to madness leading up to Autodesk university and the holidays so we will do it in photos because who doesn't like photos.

well we still wait for the water jet to get set up...

its going to be so rad !

Gabe trying to figure out what kind of tooling to order

think he just wanted a cool picture for his online dating profile.

Carl made this sweet rack to hold all the tooling for the Bluco welding table

The carts they make suck so much, I guess they cant do everything perfect.

Love this guy, that my dad Casper.

He has been building this 1929 ford A for so long, looks like spring time dreams are going to happen for this guy, hes so close!

Went back to Minnesota for my best friend Jared's wedding because I was best man.. I made a trip to the Science Museum of Minnesota, this is a great place where a lot of magic started for me being a beta test kid for Lego Mindstorms V1 in the late 1990s. I was working with the Putting Green of New Ulm,MN designing a mini golf coarse that is now located in New Ulm and matching 18 holes behind the Science Museum of Minnesota located in St. Paul. So rad to be so young and given amazing opportunities to do something no one had tried yet... teach science using mini golf

Getting all these emails about how big the new Cincinnati press had me worried so days before it was to show up we decided we should beef up the floor for the machine and lock it down, always a good idea in California with earthquakes.

Move the kitchen table out of the way. We built this beast, Gabe and I did the welding, I designed it with Carl, Arthur cut the parts on the waterjet out of 1/2 steel plate left over from an old Exploratorium exhibit and Carl and Betz did the wood work. Any 1400 lb kitchen table needs lifting hooks, the green ends started its life as a old Rouselle straight frame punch press used for stamping steel sheet metal, the machine looked like it tipped over and cracked the frame and I found it at the scrap yard, put some life back in this old machine and enjoy USA in its sheet metal glory days.

Gabe and I broke out the floor and Austin finished it by putting in the 1/2 steel rod to tie it all together. We do a lot of the work ourselves because for Gabe and Austin its important they learn how to do it and were all not afraid to just get in there and work a lot.

I machined and welded up these crazy cement inserts to hold the press to the floor.

Cincinnati has all kinds of specs you have to follow.

I think I spoke too soon about people droppin presses because only days after moving my press table I got a call from a friend saying sorry he had dropped one of my machines I was hiding druing the move, he had tried to do the move alone and rigged it wrong and dropped it, cracking, bending and throwing the machine out of alignment so I decided that the legs would be a perfect match for my lunch table. Austin pictured here taking the machine apart for scrap and to keep the legs.

all this moving has had me going crazy because I havn't really done anything for me so I decided to make the love seat right away, plus we got a new Baileigh bender that I have wanted to use so bad.

if you look above at that picture of Austin taking the machine apart you see on the legs that I can swing the machine for angle. People often ask why machines like this tilted? The reason was in a factory punching small parts tilt is not a big deal but in a factory that does long pieces like 10+ foot parts where the operators are swinging them around, you either put 15+ feet beween all the machines to allow swing around or you tilt the machines up to the sky and feed the material at a 20+ deg angle so all the long pieces stick up in the air.

Somedays I just sit around and watch Gabe teach pretty girls how to weld... I use to be 20 years old and did the same thing...

machined up bungs to allow for the loveseat to swing like the machine, I had the frame done in just a few hours.

Break time with Greg... ha ha anything that's like 160 proof and has gold flakes in it is a bad deal... you can see it on his face hes hurting.

Wires everywhere... with the new Miller Dynasty 350 and the 350p mig the shop is unstoppable.

I got the maxstar and syncrowave as backup but then I started to think from when I was back in Minnesota... What if I sent the Syncrowave back to my high school as a gift to the metal shop for opening up the door to me????

Cincinnati press brake at the factory before paint, this factory is crazy.

look at the floor 4x4 hard wood turned on end. Cincinnati was stoked to build this wild machine for me, first one like it in 10+ years.

yep... my new shirts and lab coats.

you can see on the love seat I put a uniball on it and used the old adjuster so I can angle the whole seat.

Shes almost ready to leave Cincinnati !!!

they send all these teaser photos to me..

Extended Ram, Stroke, 5 Axis backgauge... 135 tons !!!

AHHHHHHH shes beautiful ...

my dream machine !!

Myself, John Ott from Autodesk and Bob Haas from Haas CNCs at the Titan American built TV show VIP

Austin thinks hes as tough as Titan....

I figured I best stay out of this and just be the judge.

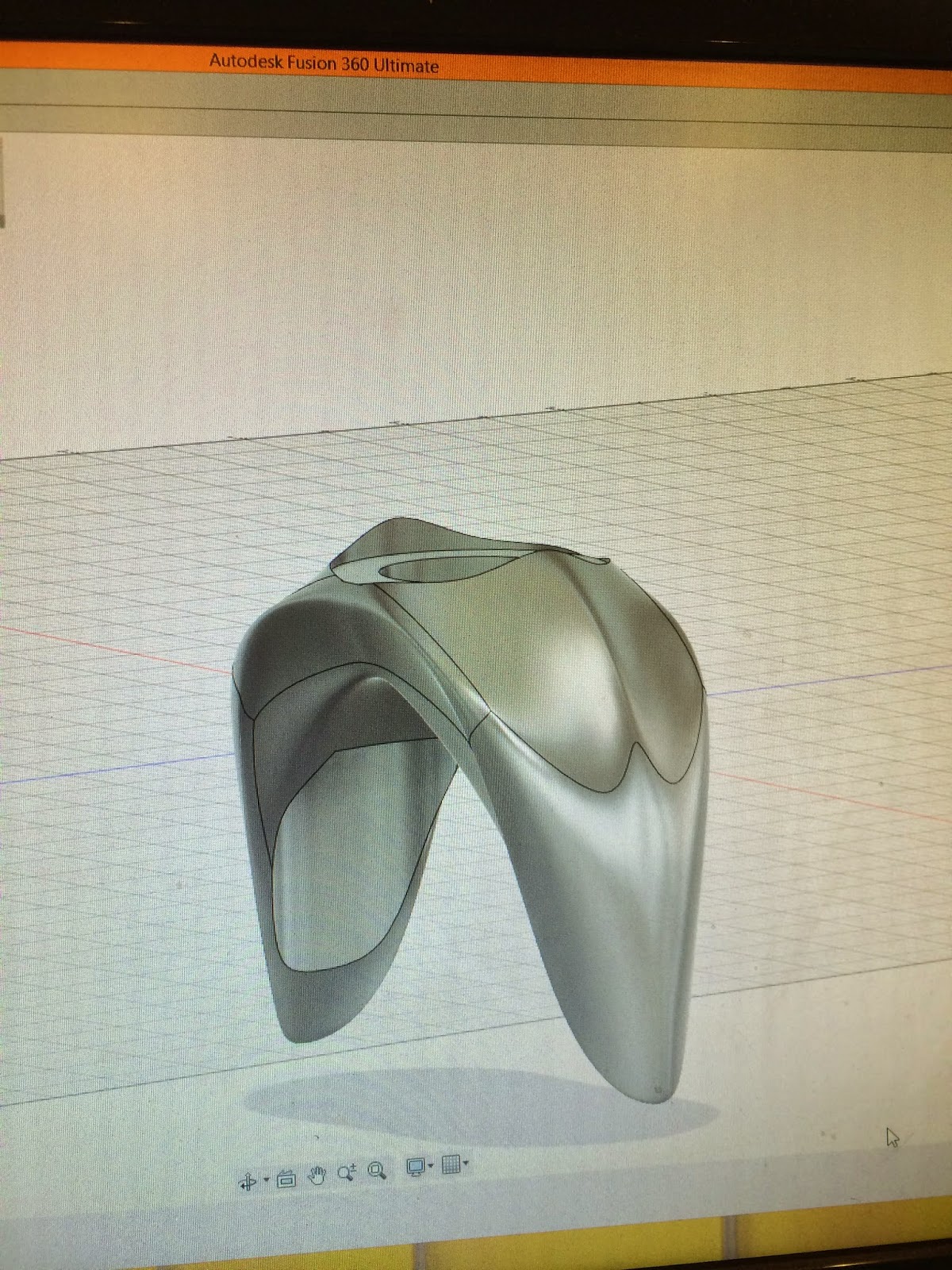

Back on the Autodesk Fusion 360 to design a concept bicycle crank

Just wait for a few posts below... I am still stoked on this thing !

Around the clock we build... using the past to build the future.

I had to sell my International Scout because I don't have the space I use to for parking.

It went to a guy that will give her lots of love... still a bit sad.

Gabe moving the Mori SL-0h around...

again another picture for his dating website profile... gotta keep that shit fresh if your going to win the top San Francisco Bay area tech ladies with your working man profile.

The calm before the storm of machine deliveries.

All the machines that were in the shop had to be pushed up to the wall to make room for the forklifts and machines that were showing up the next day.

AHHHHHHHH

after months of waiting for this custom machine to be built !

Tom Lipton from OXtool Youtube channel and Mike my Cincinnati sales man chatting

These 2 guys go 20 years back in the San Francisco bay area metal fabrication world. Its cool that I could bring them together for an exciting time in my metal fab career.

Oh man... I have dreamed of this machine for years and years and now its crazy I actually have one.

Exactly like I wanted it.

Lawson rigging moving her in...

Tom and I unloading the Haas machines extra goodies in boxes.

Tom was filming for his OxTool's youtube channel.

5 simi truck that day showed up... it was amazing to see how fast all of the moving happened.

This is the Haas ST-30ssy lathe

We shut down the street... why not so Tom was chilling waiting for lunch.

Betz got food for all the crew... such a rad shot of everyone just working and enjoying the sun.

while all the moving was happening we had no more room for the 6th simi to show up which was an autoloader to pick up the scout...

In one day... my life changed so much...

From things I loved going to new things I have longed to love showing up...

its crazy how things work sometimes....

In this photo there is so much about my life... people that are close to me, helped me, and friends that have passed... its one of those photos that's you will look at your whole life and see the beauty that no one else sees.

Only 3 years ago on the MLS blog I was doing backflips for this little DiAcro press and how it changed my life and opened doors to concept projects changing the world... Now the madness starts, this thing has a fresh history record... someone needs to write history with it so when I get old and pass it down someone says " this machine built ___________ and its changed the world of ________"

This is the cornerstone of MLS.... for 10 years this syncrowave has sculpted me in to a aerospace fabricator and its made a lot of people in to amazing people they are today like Gabe and Art that can give me a run for my money as a welder. Figured there is only one thing to do like I said above in the welder picture... Send it to my favorite high school shop teacher Mr. Stuckey of New Ulm, Minnesota Public high school and tell him to let it build the next amazing fabricators.... tools are the key to success and sometimes that's all it takes because your heart and hands do the rest.

We bought a mag drill and now hes getting lazy on me...

I work around the clock, my normal 16 hour work days catch up with me sometimes..

I feel asleep at the Exploratorium Children's museum while working on a concept project.

My work was done and my boss was stoked, then I vanished and they came to look for me... hours later my boss sent me this on my drive home.... this is a rare photo of me sleeping, I rarely do it.

A USA fabricator.... faith is in his skills and tools, oh and baby Jesus.

With my exhibit done for the museum I could focus on Autodesk University projects and stuff for myself so I figured why not just combine them so I decieded to make that crazy crank set for the high speed bicycle.

whatttttt !! those tool paths !

BAMMMM !!!

Inspired by a photo of a dove flying and not doing something anyone has done yet I came up with this madness.

The next project was to build a custom bike 7 days before leaving for Vegas

I started with a Trek to take all the parts and use that stuff.

Wheels with those sweet Shimano Roller Brakes and belt drive.

Using Autodesk Fusion 360 I designed the fork crown to be machined.

We have no air and high amp 220 so we decided to just run all the parts on my Bridgeport Boss 10 CNC. Gabe became the coolent guy and was scared of hot chips.

I needed to design some other parts to make at the show on the 5th Axis Haas cnc machine so diving back in my history books I remembered the old Kelly bars.

Adjustable bars with about 3 different positions for riding by loosening up the front bolt on the stem and moving the bars.

Heres some of the drawings of the different placements.

I got some new boots and was so stoked I needed to show them off while I machined the fork crown.

we called in Spencer to shoot video and photos of Gabe working for his online dating profile, these photos need to capture the "working man " that Gabe is so the Google employeed girls melt seeing him working with " metal "

Machining the fork crown out of a solid block of 4130 chromoly using Autodesk Fusion for driving the Bridgeport cnc.

Designing and doing cnc tool paths on Autodesk Fusion 360 - photo by spencer

Machining away... - photo by spencer.

so cool, had to look at it over a tire so I threw it on my 1938 Schwinn I ride everyday to get a look at what it will look like with forkblades.

so cool... its like a steel tongue

I finished the sprocket concept enough to get it on the bike but then classic the bottom bracket showed up as a empty box with a hole in the corner, aka " losting in shipping " so for the show it looked like it would be zip ties to attach it.

The frame for the urban assault bike coming along

I called in Adam Esposito from the Exploratorium to help me kick out the Kelly Bar concept.

Hes really good at Autodesk Inventor so it was perfect person to call for help in a time crunch.

Top view showing the 1.125 steer and the adjustable positions

Side view.. I was so stoked, the parts on the front are stainless steel 17-4 weld ons and the rear main stem body is 7075 aluminum

The rear hollow chainstay wish bone I sculpted in Autodesk Fusion turned out really cool

From concept to design and to machining in under 6 hours.

time to weld in the wishbone and chainstays

If anyone ever wonders yes MLS is sponsored... Yes we are - by the Liquor store down the street from the shop...

ha ha, we took Spencer there with us and did a photo shoot in the store, it was epic. With it being the last day of the build on the stuff before we leave for Vegas it was so important to be fueled up so I was getting some Mt. Dew and gummy bears.

Thanks to Artist in Residence at Pier 9 Autodesk named Paolo, he quickly printed out my Kelly Stem to take to Vegas. The print was done hours before we were suppose to leave for Autodesk University.

I needed them for my classes I was teaching at about 3d printing to machining to explain the benefits of 3d printing before running a job on the cnc machines.

Gabe and I built this custom tool box for going out on the road teaching Machining.

Its got a Kennedy tool box filled with MariTool CNC holders, 5th Axis vise and 2 Orange Vises mounted on it. It also carries all the material for demos and a 42" flat screen that mounts to the back of the cart to show what were doing on the computer. its the swiss army knife of tool boxes.

Our luck it started raining.

hammering thru the night in the ratty shop truck, we got to see the sun rising over Vegas..

Well I did... Gabe was sleeping dreaming of dancing girls....

Setting up for the show with Gabe, getting all the bikes out and setting up the Haas with tools.

I was flattered to see my face on the Autodesk posters cover the trade show !

here is my prototype 3d print of the MLS Kelly Stem/bar combo in front of the booth.

Ken from Haas getting the UMC750 ready to cut... me thinking about what I can eat and the bikes ready for the show, the booth was to look like my workshop with unfinished projects all over...

They nailed it.!

As soon as were ready setting up the booth we had to run across the place to make it in time to see Carl talk to over 10,000 people about the future of making and where Autodesk is going in the years to come. pictured behind Carl is a crazy Kuka Robotic arm with a Mig welder and it can " 3d Print " metal structures like bridges and sculptures using tacks as build material, SO RAD ! If you remember last year Carl talked about MLS during this talk in front of 10,000 about the leg that Bill and I designed for the a girl injured in war while serving the US Military.

I gave a few talks about manufacturing to groups and taught a few classes at Autodesk University.

Pretty neat to get to see what other machinist and designers are doing around the world to make sure I am up to speed on the current industry happenings.

TJ from the 3dRV was there so we did a filming of how 5 axis cnc machines work and understanding 5 axis movements. Pretty cool because these are videos that focus on education.

During the show some of the kids that were part of the Autodesk Education Robotics contest had a breakdown on their robot, had Anthony from Autodesk not heard about this and brought the kid to us the team would have been out of the completion. Ken from Haas and I were able to chuck up the part and do a second operation clean up pass on it and fix it. This is truly a amazing photo showing the next generation of machinist being made because of the willing ness of a few people to shut down and break down the tradeshow demo to do a repair and make some kids really happy.

Later that night I was invited to a cool VIP party for the crew from

Made In Space which is a group that has built the 3d printer that's on the space station. At the party they had the back up printer sitting on the table so I could use it as a place to rest on and put my beer on top for style points, ha ha. It was super cool to see the challenges they had to overcome because of no gravity and how extruding hot plastic doesn't just lay down without gravity. Good group of people working on this project, glad to get invited to the party and drink all night.

maybe next year I will get one of these for my MLS Aerospace name badge at Autodesk University.

ha ha, its funny to see people at the event with like 15 or more of these hanging off their chest... at a point doesn't it get so long that you can't go to the bathroom without having to take it off. Annoying....

I was sooo stoked to get to hang with my favorite crew from the Autodesk 3dRV

Also stoked to see old friends and meet soo many people and thanks to all the people that came up to me and said they love the MLS blog and Instagram feed, that made my day !

Back to the shop...

First day back, Gabe smelled like vanilla because of the girls at Little Darlings...

He was heart broken and finically broken too.

Carl was making motorcycle parts at Pier 9 on the Haas, we just got back from lunch so that's why he doesn't have glasses on. Pretty cool to see the CEO working to break his own software products.... this is how America was built kids, the push to always be better !

The whole Santa Cruz Syndicate race team showed up at the shop to say high and pose for a photo.

Always rad to show Marshie - Gregs mechanic and inventor of the

Marsh mud guard and long time hero and Mountain bike legend Steve Pete the shop and the projects.

Back to working... during the holidays so no one bugs me...

Waterjet and Cincinnati press still wait for 480v power for the 7 months.

The classic thing of dealing with people in Berkeley and the power company... don't even get me started.

Thanks to Wilton for the F-clamps.. they are so nice and make life so easy.

not just staying it because they gave me stuff but they make the best Clamps and Vises...

This little 4.5 inch Wilton Tradesman is such a great little vise for general work plus its made in the USA still and built off their famous Bullet vise.

I made Carl a Christmas gift...

Sputnik flying around the world, I call it...

" Baby on Board "

The flow is starting to get good in the shop...

except the shin buster Ammco Shaper that sits in the middle of nowhere for the last 4 months.

Eric over at

Orange Vise setting up my VM3 with some sweet working holding.

I am sitting here right now typing on this table...

The phone booth in the shop is the little 1992 Mori SL-0h

this thing is so neat with a 6k spindle, chuck and 5c nose.

you can run it 24/7 and it just doesn't give up.

Lucky for us that Haas machines run on 220v and not 480v because we hooked them up over the holidays so we can keep going!

The big dog lathe - The Haas ST-30ssy with 3" thru spindle for working huge round bars, it has 24 tool stations inside 12 which are live which means I can, drill, mill, saw or anything you can dream of doing inside just like a mill, this thing is so sweet!

My new baby - Haas VM-3 mold maker cnc machine... shes got all the bells and ready for madness...

Its ready for 4th and 5th axis work, its 40x26x 25 high work area and has very tight ball screws for extremely tight work, we got special memory for all my wild ideas on both machines and everything option in the book basically because we have goals for 2015 so get ready world !!!!!!!

Enjoy everyone

Happy 2015 from the Monkeys here at MLS